Sustainability is changing many fields, and aviation is no different.

Sustainable Aviation Fuel (SAF) is growing in Australia thanks to developments in power-to-liquid (PtL) and biogenic technologies. The switch to SAF is not only necessary but also timely. By 2050, air traffic will have doubled, and emissions from planes will be back to where they were before the pandemic1.

Australia is taking measures to develop a domestic SAF sector by cultivating and processing local biogenic feedstocks, establishing green processing facilities, and expediting certification and distribution2. These steps are cutting emissions, strengthening fuel security, creating jobs and driving the country toward its net-zero goals.

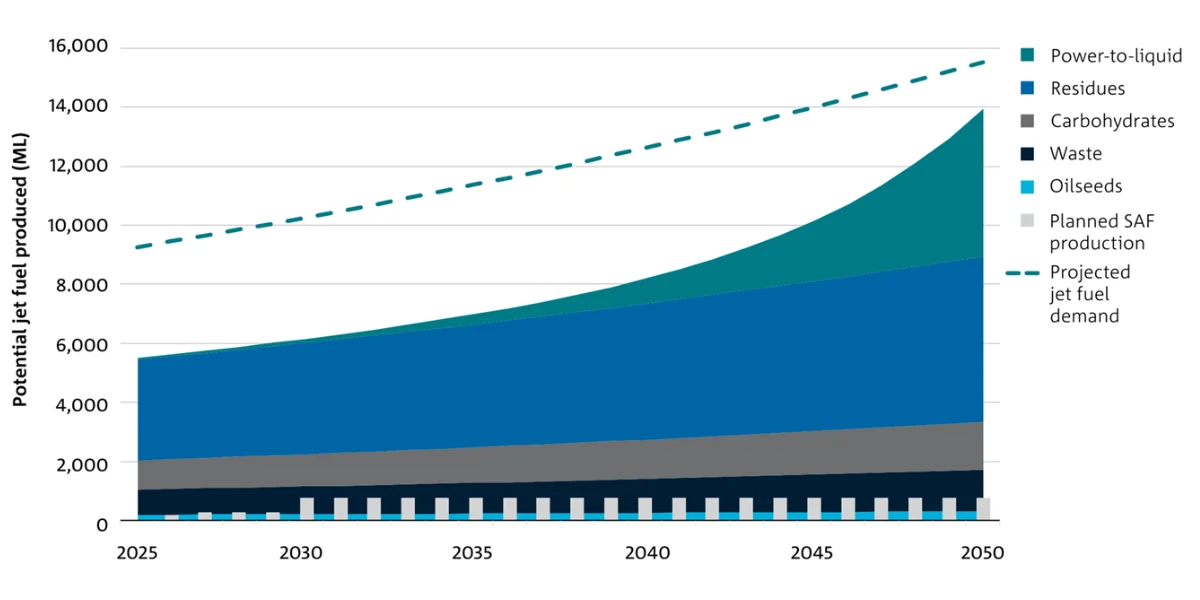

This shift, however, isn’t just about reducing emissions — it’s about leading the way in sustainable aviation. By 2025, Australia could produce up to 5 billion litres of SAF, growing to 14 billion litres by 20503. The economic upside is just as big, with SAF opening the door to billions in potential investments.

Beca is actively involved, working with industry and government to turn SAF ambitions into action. From feasibility studies to engineering solutions, we’re helping Australia take off toward a cleaner aviation future.

Source: Photo by Ross Parmly

What is sustainable aviation fuel?

SAF is a revolutionary way to deal with the environmental problems that aviation faces. By definition, SAF is made from sustainable feedstocks, which can be anything from used cooking oil and farm waste to green hydrogen and non-biogenic resources. Unlike regular jet fuel, which comes from fossil fuels, SAF burns cleaner and produces a lot less pollution — up to 80% less over its lifetime than regular jet fuel4.

Why does SAF matter so much for Australia’s aviation future? Aviation makes up about 2.5% of global carbon emissions, so switching to SAF isn’t just good for the planet — it’s key to helping the industry hit net-zero targets5. But the benefits go beyond sustainability. SAF creates new business and job opportunities, particularly in rural locations with ample feedstocks. And so Australia's investment in SAF not only reduces emissions but also builds a stronger, more resilient economy.

The benefits of SAF, both environmental and economic, are significant. Switching to SAF lets Australia tap into its rich resources and existing infrastructure to strengthen fuel security, unlock new export markets and drive investment in regional areas. While lowering aviation emissions, we’re also aiming to position Australia as a global innovator in sustainable fuel technology.

The current state of aviation fuel in Australia

Currently, Australia's aviation industry depends heavily on traditional jet fuel, consuming about 7,700 million litres annually6. The airline industry has made commitments to decarbonise and a reduced reliance on traditional fuels is an important pathway in achieving these commitments. Transitioning to SAF is critical to addressing these issues and meeting the expanding demand for jet fuel, which is driven by increased worldwide travel.

The Australian government — alongside industry giants like Qantas and Virgin Australia — is pushing hard to grow the sustainable aviation fuel industry. They recognise that the future of aviation has to be cleaner, and SAF is a big part of making that happen.

Already, progress is being made. Qantas made history in 2012 when it used sustainable aviation fuel on the first commercial flight7. As of right now, Brisbane Airport is still conducting trials to see how SAF may be included in regular operations.

Meanwhile, Australia is reinforcing its commitment to low-carbon aviation by collaborating with organisations such as the Jet Zero Council and creating critical collaborations with industry giants such as Boeing Australia8. And the goal is to create a better, more sustainable way to fly.

Source: CSIRO

The environmental benefits of SAF

Switching from traditional jet fuel to sustainable aviation fuel is a real, practical step toward lowering carbon emissions in aviation. Made from renewable sources like biomass and waste, SAF could cut emissions by up to 80% — a significant shift in the right direction. It’s not just about reducing carbon; it’s about building a more sustainable, reliable energy future that reduces our dependence on fossil fuels and keeps the industry moving forward.

However, not all SAF feedstocks are created equal — each comes with its own considerations. Take bio-based SAF, for example. Sourced from materials like biomass and forestry by-products, it helps put lower-grade wood to good use. But if not managed responsibly, it could have unintended environmental impacts, so careful oversight is key.

On the other hand, waste-derived SAF, composed of materials like municipal solid waste (MSW), creates a mutually beneficial situation by reducing landfill waste and the need for additional land use. Assuming they are managed with care and an eye toward the future of the environment, both methods can contribute to a more sustainable future in aviation.

Technical aspects of SAF production

SAF production begins with selecting and preparing various feedstocks, from biomass and waste to non-biogenic sources like hydrogen and carbon dioxide. These materials form the backbone of SAF, each with its pathway to becoming jet fuel.

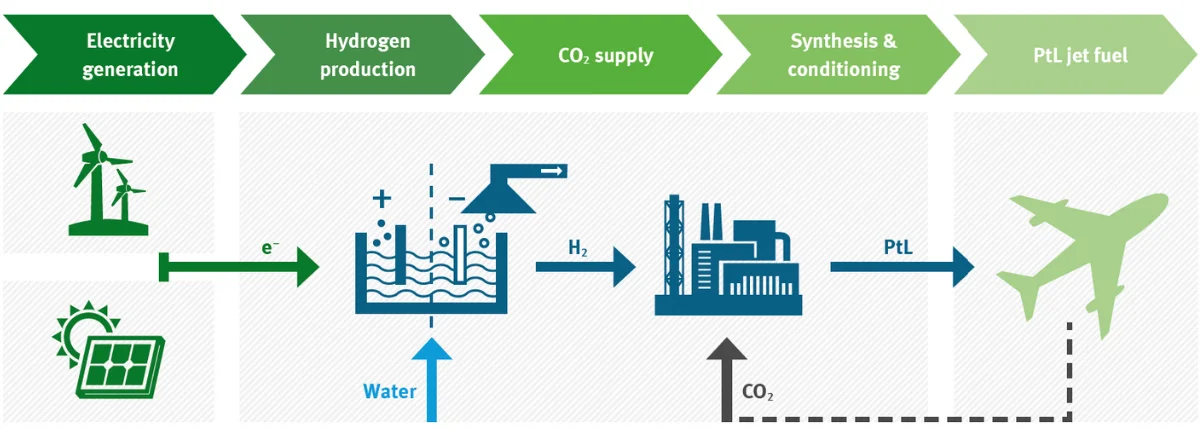

Power-to-Liquids (PtL) is a new and fast-developing way to make SAF. It uses renewable energy to create synthetic fuels, making it a practical, lower-emission alternative to traditional jet fuel. This approach helps the aviation industry cut carbon emissions and move toward a cleaner substitute to traditional jet fuels.

Source: ICAO

Here’s how it works: Electricity — ideally from renewable sources — powers electrolysis to produce hydrogen. That hydrogen is then combined with captured carbon dioxide — either from industrial emissions or directly from the air — to create synthetic hydrocarbons. These hydrocarbons are refined into sustainable aviation fuel, reducing carbon emissions and making better use of renewable energy in the process. It’s a smart, future-focused approach that moves aviation closer to real sustainability.

While PtL is gaining traction, other methods, such as Hydroprocessed Esters and Fatty Acids (HEFA) and the Fischer-Tropsch (FT) process, also play critical roles. HEFA, for example, converts fats, oils and greases into hydrocarbons that closely resemble traditional jet fuels. Meanwhile, the Fischer-Tropsch process turns a variety of carbon-rich materials into syngas, which are converted into liquid hydrocarbons.

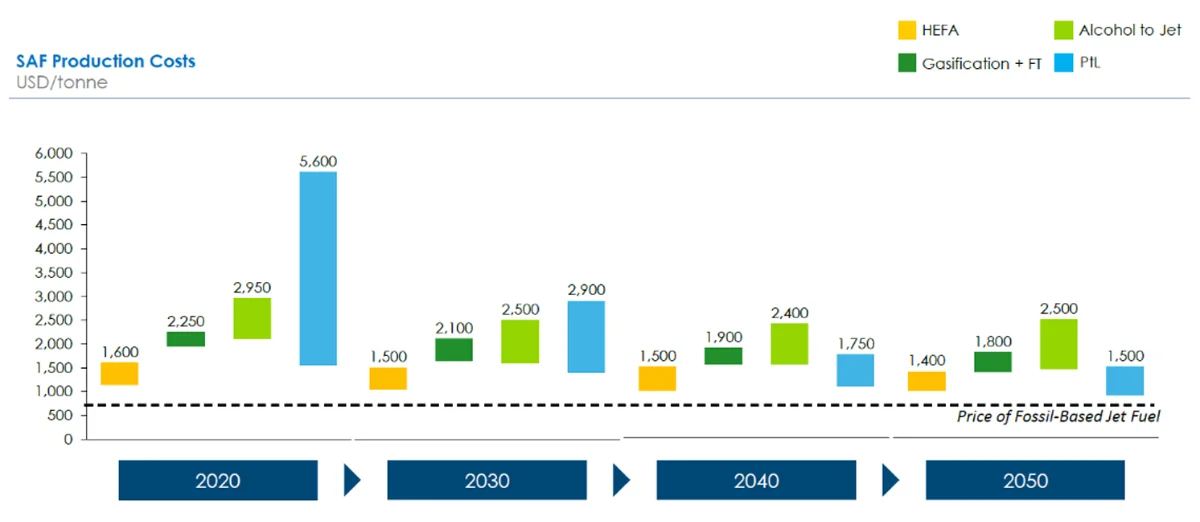

Each of these methods has its strengths and challenges, from feedstock availability to developing the technology and cost-effectiveness. But what they all have in common is the ability to cut aviation emissions in a big way. By making the shift to lower-carbon fuels, the industry is taking real steps toward a more sustainable future for air travel.

Our commitment to driving SAF technology

At Beca, in conjunction with our partners such as Wood Group, we’re dedicated to helping our clients make informed choices in SAF solution applications, creating a viable way to lessen the aviation industry’s environmental impact. By focusing on both the environmental benefits and the technical aspects of SAF production, we are making strides toward a cleaner and more sustainable aviation sector.

Making SAF a success isn’t a one-company job — it takes strong partnerships across industries. Collaboration is critical to implementing SAF technology in a way that benefits both the environment and the aviation sector. Businesses may work together to make SAF a viable, cost-effective alternative to standard jet fuel. It's a win-win situation — reducing emissions while making aviation economically viable for the long term.

Overcoming challenges and seizing opportunities in SAF production

How can scaling SAF production effectively address both the commitment to going green and the significant economic and regulatory challenges involved? Right now, SAF costs more than traditional jet fuel, mostly because of the complex process of sourcing and refining sustainable feedstocks9.

Regulations need to keep pace with progress. Clearer policies would make it easier — and more affordable — for businesses to invest in renewable fuels. SAF isn’t just about being greener; it needs to be a practical, cost-effective choice for the aviation industry to truly take off.

Source: KFW

Producing SAF comes with its fair share of challenges — high costs, securing a steady supply of feedstocks and the big investment needed to build new production facilities. But there’s good news. Government incentives, like subsidies and blending mandates, can help ease the financial burden, while advancements in technology are already driving costs down. With the right support, SAF can become a more accessible, cost-effective solution for the aviation industry10. Collaboration between governments and businesses is also key to creating a stable market for SAF11.

Consider how this might affect not only Australia but the entire world. By advancing SAF, Australia can lead by example and demonstrate the viability and advantages of sustainable aviation. A strong SAF industry here could inspire global action, driving down aviation emissions on a much bigger scale.

Get involved with the future of aviation fuel in Australia

The move toward sustainable aviation fuel is a big step in making Australia’s aviation industry more sustainable, but it comes with real challenges. At Beca, we’re working to make SAF a practical, scalable solution, balancing environmental benefits with industry needs. We’re focused on real-world impact — helping reduce emissions while ensuring SAF can be integrated effectively into Australia’s fuel mix.

If you want to learn more, explore our insights on SAF here, or get in touch to see how we can work together to shape a cleaner, more sustainable future for aviation.

Sources

- Australian Government | Department of Climate Change, Energy, the Environment and Water - Australia's emissions projections 2023

- CSIRO - Sustainable Aviation Fuel Roadmap 2023

- CSIRO - Fueling Australia's future sustainable aviation industry

- Bioenergy Australia - Sustainable aviation fuel

- Our World in Data - What share of global CO₂ emissions come from aviation?

- Queensland Government & Deloitte - Catalysing sustainable aviation fuel (SAF) in Australia

- Phys Org - Australia's Qantas makes first commercial biofuel flight

- Jet Zero - Producing sustainable aviation fuel for a better Australia today

- Ibex Publishing - Is sustainable Aviation Fuel (SAF) Really More Expensive?

- New Atlas - Lignin breakthrough unlocks cost-competitive, carbon-neutral jet fuel

- Australian Aviation - Industry applauds 2024 budget's aviation sustainability funding

Authors

Shane Gowan

Business Director - Energy Transition & Decarbonisation