Digital twins promise to be a vital part of our working future. Anyone who has an interest in looking after an asset, be it a bridge, a factory, a pump, a well, a road, a city or, perhaps more controversially, people or a business, would do well to understand what the state of the art is in ‘digital twinning’ right now and where this capability is headed.

What and why?

So, what is a digital twin and why should you care? As a recovering academic, there’s nothing I like more than a definition, so let’s get it out of the way!

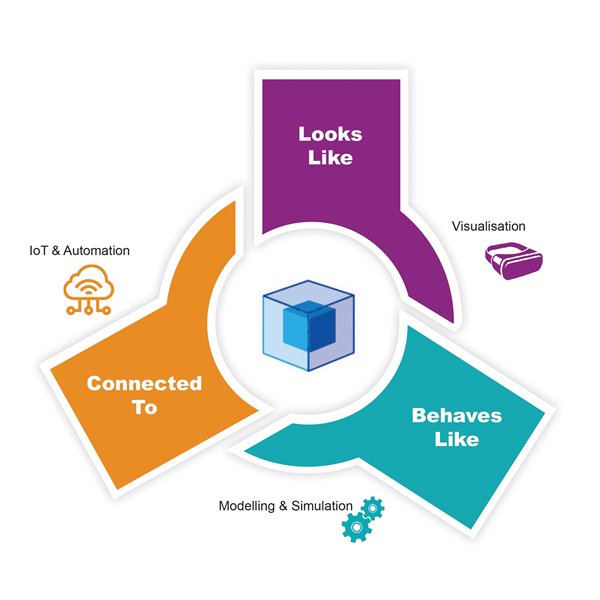

A digital twin is a high-fidelity representation of the real-world that looks like, behaves like and is connected to the real world, to improve understanding for decision making.

– Stephen Witherden, 2017.

The benefits of being able to plan, design and operate a ‘living, breathing’ replica of your asset are multiple! Here are just a few:

- Reduced capital spend and maintenance costs

- Higher OEE / more output

- Lower disturbance risk / better asset resilience

- Lower operating overhead

- Improved return on investment

- Better risk management

- Better customer service

- Improved health and safety training and systems

How? Does this require a brand-new range of tools and technologies?

More on the ‘how’ follows. The interesting thing to note is the speed in which we can deliver digital twins to our clients, by working with them to leverage their existing data and technologies, which we are able to integrate with off-the-shelf technologies and our own digital twin platform.

Young and promising technology

At a high level, “looks like” involves visualisation, “behaves like” is a simulation and “connected to” involves technologies like IoT and actuation through automation. So, how can you extract most value?

Well, we’re all in the process of figuring it out! There’s a lot of buzz about digital twins, and I worry that technologists like myself may sell an expansive long-term vision but in the short term deliver something which falls short and tarnishes the idea. Just like “Artificial Intelligence” had its fair share of dead ends that tarnished the overall name pre 90’s, so too could Digital Twins and it’s only the start of the journey for this very young and very promising technology.

Fully integrating ideas and assets

Why do we care? Well, from a Beca perspective, we care very much!

Engineering is all about developing an understanding of the real world through science and applying that understanding to facilitate a change in the real world, typically in the form of designing and building things.

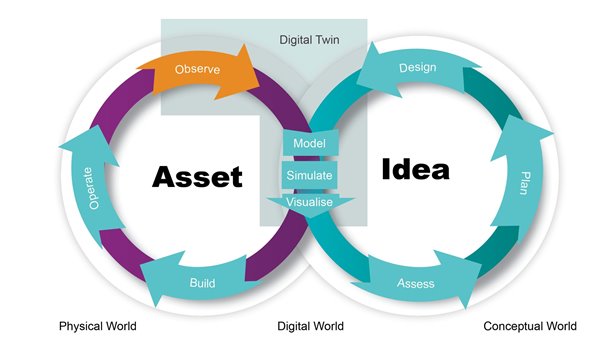

On the right side of the diagram we have the “conceptual world” where we are understanding visualisations of assets, be they 2D drawings, 3D models, photos or spreadsheets and on the left-hand side we have the physical world where the actual asset lives and is operated by the asset owner.

Multiple digital and IoT tools can be brought together now to integrate the physical and conceptual:

Operate

On the operational side, our clients operate their asset, this involves using the asset to deliver that asset’s purpose, be that producing products, delivering a service, providing infrastructure or housing people. Our clients are becoming ever increasingly sophisticated in their use of digital technologies to understand how they can use their assets.

Observe and model

While operating the asset, we observe the real-world asset (or system of assets), this could be something as simple as visiting the asset in person and watching it in operation, or as sophisticated as a point cloud scan combined with live IoT data. We model these observations in a representation of the asset. This could be as simple as an Excel spreadsheet or sketch or as sophisticated as a detailed engineering model in 3D.

Simulate

We might simulate the expected behaviour of the asset, once again this could simply be a calculation in Excel or as complex as a full component analysis, fire analysis, capacity or pedestrian model, the list goes on. We visualise those results and assess the expected performance of the asset against what the client wants.

Plan, design, optimise

Usually, the client wants to change something, be it a change to capacity (more people, litres, widgets). Incorporating what the client wants, we plan the next steps. The plan informs a design activity which in turn is modelled, (potentially) simulated, visualised and assessed again.

Build

We iterate in the engineering loop until the design is ready for construction. This might be as simple as the installation of a single piece of equipment or as complex as delivering a whole new factory / building / piece of infrastructure. I have captured this in the unassuming word: build. This change impacts on the asset and we have come full circle.

Going back to our definition of digital twins looking like, behaving like and connected to the real world, we can see how digital twins operate in the Observe, Model, Simulate and Visualise space. Although there are many solutions in this space both for operations and for engineering, they are not fully integrated and so don’t result in the joined-up benefits offered by a consolidated digital twin. So, what are those benefits?

Benefits

Gartner estimates an overall 10% improvement in “effectiveness” by 2021 (Gartner, 2017) whilst PwC have measured a 1.5 – 3% improvement in total cost of ownership of assets for BIM level 2 (PwC, 2018).

In mapping benefits to the asset lifecycle, we see benefits at following stages:

Key benefits

Maintenance

- Reduced maintenance costs due to having accurate information about the condition of the assets easily accessible to maintenance personnel

- Efficient resource allocation due to being able to provide maintenance information to remote third parties

- Improved service speed, due to having the correct tools and information to perform the maintenance activity in the first instance

Engineering

- Reduced cost of services since the digital twin gives engineers a running start in terms of understanding the existing asset

- Improved project velocity due to improved coordination using a joined-up view of the asset base

- Reduced capital spend

- Improved Return on Investment since engineering ideas can be tested in the model before a change is considered

Production

- Higher OEE / more output

- Lower disturbance risk / better asset resilience

- Lower operating overhead

- Improved Return on Investment

Occupational Health & Safety

- Reduced OH&S risk due to superior health & safety training, virtual Gemba walks and getting hazard information into the hands of all stakeholders

- Quicker response to incidents due to having accurate information about assets, hazards, risks and incidents in the hands of decision makers

Quality

- Reduced cost of support services

- Quicker response to quality incidents

Inventory

- Reduced inventory cost due to better operational modelling and prediction

- Better customer service

- Less business penalties due to FG disruptions

Procurement

- Reduced cost of purchasing services due to being able to communicate requirements to contractors and vendors more accurately: measurements can be taken directly off the twin

- Better customer service

How much Fidelity = a digital twin?

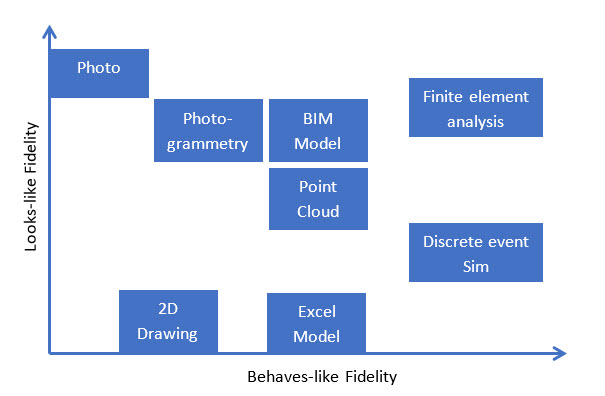

Fidelity is the degree of exactness between the digital representation and the real world. We have three dimensions of fidelity we must consider: looks like, behaves like and connected to.

For example, a photo is a perfectly accurate “looks like” representation of the real world but has no fidelity in terms of “behaves like” since it is just a 2D image. There is quite some debate as to how much fidelity is required before we can use the moniker “digital twin” on the one hand, if we call a 2D photo a digital twin we run the risk of making the term meaningless. Alternatively, if we hold out for a fully immersive 1:1 accurate simulation, we may never realise any benefits at all. For this reason, I would like to talk more about fidelity as a continuum.

Looking at the “connected to” fidelity continuum is more to do with the degree to which the digital twin is plumbed into the real world.

So, there we have it, a digital twin is a high-fidelity representation of a real-world that looks like, behaves like and is connected to the real world the purpose of which is to improve understanding for decision making.

Making it happen

The interesting thing is the speed in which we can deliver digital twin pilots to our clients, by working with them to leverage their existing data and technologies, which we are able to integrate with off-the-shelf technologies and our own digital twin platform.

We’re excited about helping our clients get the most out of digital twins. If you’re interested in learning more about how digital twins could be used to help your organization– please get in touch!

References:

Gartner. (2017, September 18). Prepare for the Impact of Digital Twins. Retrieved from Smarter With Gartner: https://www.gartner.com/smarterwithgartner/prepare-for-the-impact-of-digital-twins/

PwC. (2018). Quantifying the benefits of BIM. Retrieved from Capital projects & infrastructure publications: https://www.pwc.co.uk/industries/capital-projects-infrastructure/insights/quantifying-benefits-of-bim.html

Stephen Witherden

Technical Director - Software Engineering

New Zealand

New Zealand

Australia

Australia

Singapore

Singapore