Following the COVID-19 crisis of 2020-21, what was once considered “normal” isn’t available to us anymore, and “business as usual” even less so! Due to its physical nature, the construction sector was greatly impacted by the supply chain disruptions and physical distancing requirements the pandemic brought about.

However, Digital Twin technology offers a viable way to address these issues and improve the industry’s productivity frontier, as Beca’s Fara Mosavari and Luke Carvell discussed in their February 21 webinar at the ‘Digital Construction Online Australia’ conference.As workers retreated to the comfort of their kitchen tables and physical distancing requirements were put in place to deal with a frightening new virus, the global construction sector was on the frontline. In many cases, large construction sites were completely shut down – with this reflected in the sectors growth being revised down from 3.1% to just 0.5% in 2020.

Beca wasn’t immune to these challenges either, with our engineers and consultants who serve the construction sector facing the same conditions as our peers; namely supply chain disruptions, a shortage of subcontractors and materials, uncertainty in share prices leading to reduced investor confidence, disconnected project teams and a reduction in site visits that made it very difficult to manage complex projects.

From crisis comes opportunity: Preparing for a digital future

Whilst these challenges were frightening and real, they’ve also pushed the construction sector to fast-track its adoption of digital technology and address one of its long-standing issues – productivity. COVID won’t be the last shock the sector faces, and construction leaders will be defined by what they do along the three dimensions of managing a crisis: Respond, Recover and Thrive.

In fact, according to a 2020 Accenture study, companies that fast-track their digital adoption by augmenting workers and engineers with digital collaboration capabilities, automating low value-added activities, sharing data for rational and insight-driven decision making, and reinvent their relationship with third parties, clients, supplier and subcontractors - will be strengthened and ready to succeed in a post-COVID-19 world.

Beca have already implemented these solutions within our own company, including the move to the Microsoft 365 suite for seamless remote collaboration and most notably – the widespread adoption of BIM (Building Information Modelling) and Digital Twin technology to enable complex construction projects to be managed from anywhere at anytime.

“Whilst these challenges were frightening and real, they’ve also pushed the construction sector to fast-track their adoption of digital technology and address one of its long-standing issues – productivity”

Digital Twins: Recreating the physical world in virtual form

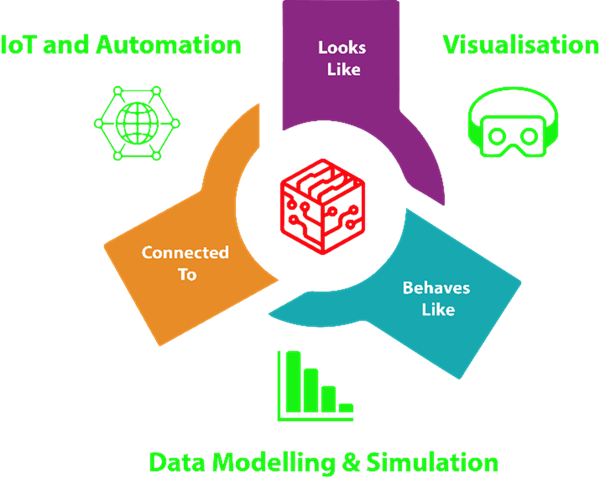

A digital twin is a high-fidelity representation of the real-world that looks like, behaves like and is connected to the real world, to improve understanding for decision making.

At a high level, “looks like” involves visualisation, “behaves like” is a simulation and “connected to” involves technologies like IoT and actuation through automation.

In other words, a Digital Twin is a virtual, 3D model of a real world physical object such as a building. And by virtue of its nature, Digital Twins allow people to collaborate on the design, construction and maintenance of that physical structure from anywhere, in real-time – negating the barriers of distance and on-site safety considerations.

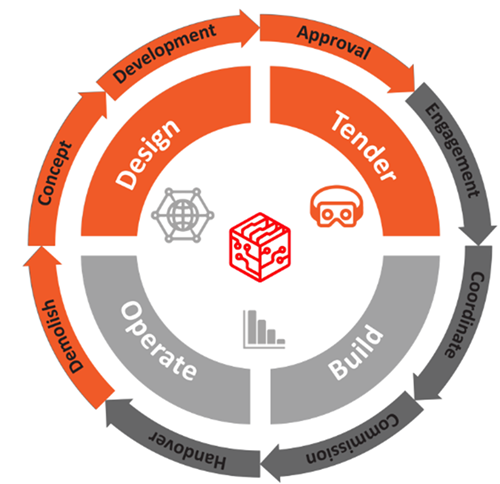

So how are Digital Twins used in practice? They can do many things, from supporting communication between engineers working on a construction project from initial concept design, to providing base conditions interpretation. As the project lifecycle continues, virtual asset representation is matured with changes being captured and updated for seamless project team coordination. In a word, Digital Twins provide the conduit for clear and concise communication!

“A digital twin is a high-fidelity representation of the real-world that looks like, behaves like and is connected to the real world, to improve understanding for decision making”

Solving everyday problems: Why the right information is key

Whilst the power of Digital Twins, combined with BIM technology to take project collaboration to the next level is undeniable; like any digital model a Digital Twin is only as good as the information which underpins it.

In many corners of the construction sector, knowledge and adoption of BIM technology and Digital Twins is limited, with some more traditional practitioners still relying on paper-based models and design files spread across multiple platforms. The beauty of a Digital Twin is how it brings to life all the modelling regarding a physical structure through the one elegant, interactive and 3D representation.

For any organisation considering adopting Digital Twin technology, you first need to clearly define your objectives. This for example could include:

- Computational scenario optimisation for design and or operational capacity opportunities

- Lifecycle graphical and non-graphical information collated of the physical asset in the virtual world

- Shared Centralised Repository accessible

- Shared resources to drive consistency of data – templates and standards

- Connected communication with physical assets informing business tasks and programme

You’ll also need to clearly establish your requirements for a Digital Twin to work effectively as a ‘single source of truth’ for your project. This may include identifying responsible parties, scope, activities and timeframes, information standards, production methods and procedures, shared resources and more.

Keep in mind your Digital Twin is a single source of truth, so it’s never about reproducing information but instead enabling seamless integration. Once the right project functionalities are understood we can map how this can be portrayed with use of Digital Twin technology.

And this is why we establish Exchange information requirements for clients or projects. This documentation can be used for contractually engaging any supplier, vendor, consultant, contractor and set the standard for what information should be provided when, how it should be provided and by who.

Digital Twins in practice: A real world example

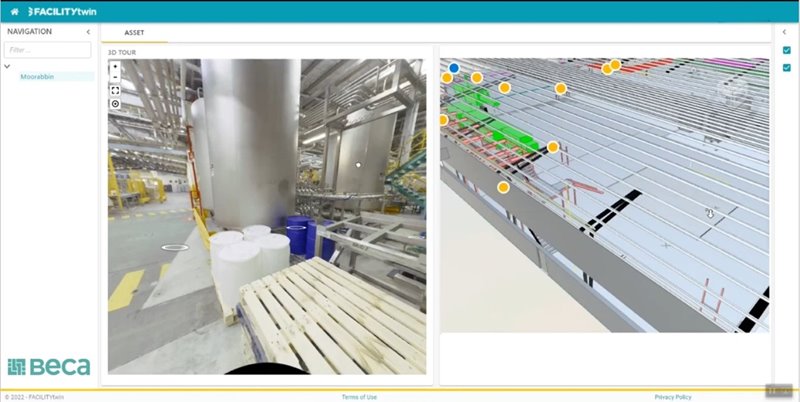

We’ve spent a lot of time talking about the benefits of Digital Twin technology for bringing to life a physical structure in digital form and enabling new levels of collaboration and communication for engineering teams working on complex construction projects. Now, we’d like to share a real world example of a construction project where Beca applied our own proprietary Digital Twin platform FACILITYtwin, to achieve tangible results.

As you can see in this utilities project below, we brought together 3D spatial capture and BIM modelling, linked with asset data and functions. It also provided the opportunity to integrate documentation such as health, safety and maintenance procedures all in the one place.

This content was originally presented by Fara Mosavari and Luke Carvell at their ‘Digital Twins for Digital Communication’ webinar on February 21, part of the bigger Digital Construction Online Australia conference. A full recording of their session can be viewed here.

More information on Beca's Digital Twin platform, FACILITYtwin can be viewed here.

More information on Beca's Digital Twin platform, FACILITYtwin can be viewed here.

About the Author

View on LinkedIn

Email Luke Carvell

Luke Carvell

Digital Innovation Leader - T&I Australia

New Zealand

New Zealand

Australia

Australia

Singapore

Singapore